How our punnet inserter work

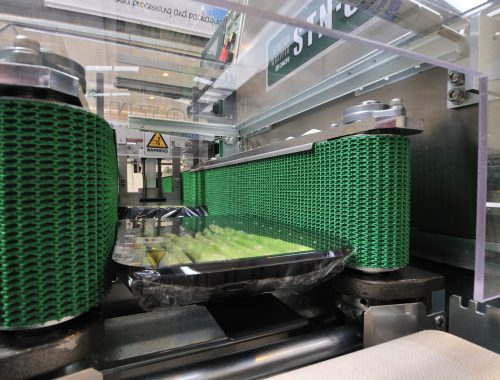

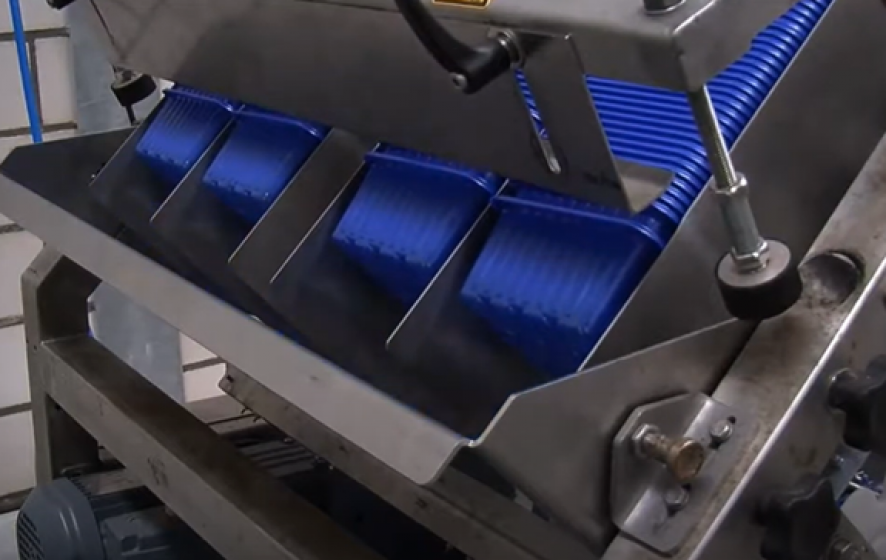

The line is able to automatically singulate a stack of empty crates. Then the stacks of punnets are separated and placed in the empty crates. After that, the crates filled with empty punnets are piled up again. The line consists of a conveyor belt, a destacker, a separation unit and a stacker.

The destacker lifts a stack of empty crates and then places them one by one on the conveyor belt. The conveyor belt moves the crates to the separation unit, which ensures that the empty crates are filled with punnets. There, the filled crates are stacked again. As soon as the desired stack height is reached, the conveyor belt discharges the stack. An operator moves the stack to a certain location in the warehouse. Only one operator is needed for this task, where operators were previously required to transport stacks of empty crates, place stacks of punnets and remove stacks of punnets from the line.

Use of our punnet inserter

The punnet insert is frequently used, especially in the agri-food sector. This machine has been developed for the mushroom industry, but can be used as well for soft fruit such as strawberries or raspberries.

Advantages of our punnet inserter

The advantages of an ARCO tray sealer are:

- The punnet inserter increases production capacity;

- The punnet inserter provides higher efficiency;

- A single operator can achieve the same production volumes as multiple operators manually placing the trays.

Other possibilities

In addition to punnet inserters, ARCO also has stretch wrappers, tray sealers, case closers, case erectors and punnet dispensers. We are happy to help you find the most suitable and most economical solution for your organisation.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. We realize this with products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, you will need more than good service only. View the supplement to our hardware services below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en