How our PLC software work

PLC (programmable-logic controller) is used to control production lines and machines. The PLC is a computer with a microprocessor that sends the correct information to the relevant machines in the line.

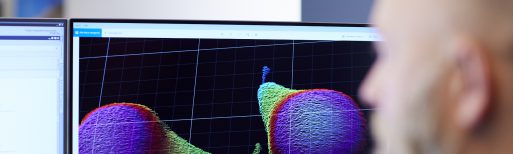

In a PLC system it is possible to program exactly what each machine on the production line has to do. A PLC system not only controls, but is also very suitable for signaling malfunctions. In combination with an HMI screen (touch panel), information from the PLC is easily displayed on the screen. For example, malfunctions can be visualized for inspection. The production line can also be operated from the HMI screen. This allows the versatile and swift adjustment of settings to ensure that the production process runs smoothly, efficiently and quickly.

Application of our PLC software

PLC systems are integrated into every production process we deliver. PLC systems provide secure and reliable control processes in the agri-food sector, the logistics sector, the recycling and bulk sector. It is the brain of a production line. For instance, it controls the weighing by forwarding scanned barcodes or bring the sieving process to a halt when the collection container is full.

Advantages of our PLC software

The advantages of an PLC software are:

- Remote service is possible;

- Data is visualized on an HMI screen;

- The HMI screen easy to understand;

- Remote I/O equipment;

- Easy integration with your system;

- State of the art communication protocols (profinet, TCP/IP).

Other possibilities

Are you looking for the best and most reliable software solutions for your business? Have a look at our warehouse management systems (WCS) and our AGR software.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. With products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of your equipment, simple options for making upgrades and the flexibility to respond quickly and efficiently to changing market demands. To achieve this, more is needed than just good service. View the supplement to our hardware solutions below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en