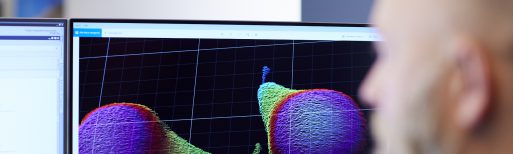

How our zipp sorters work

At the beginning of the line, a packet is identified by means of a scanner. Depending on the information (think of package dimensions, weight, barcode, etc.), a package goes through the zipp sorter and will be sorted at the correct angle. Using intelligent software, the zipp sorter knows exactly at what time and in which direction the package must be transported.

Use of our zipp sorters

Choosing the right sorting solution is an important decision. The most suitable sorting solution depends on various criteria, such as the required capacity and the properties of the products. The Zipp sorter is mainly used in the logistics sector. ARCO develops, produces and implements the right sorting solution for every application.

Advantages of our zipp sorters

An ARCO Zipp sorter offers the following benefits:

- Packages on the conveyor belt are sorted at the right time without damage;

- Can handle a large volume flow;

- The product flow can be optimally controlled using ARCO’s smart software.

Other possibilities

In addition to zipp sorters, ARCO has many other sorting solutions. ARCO builds complete material handling installations that ensure optimum throughput of the sorting line. Also take a look at our crossbelt sorters, transfer units and diverters. ARCO advises you the best suitable solution and takes care of this from A to Z.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. With products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, more is needed than good service. View the supplement to our hardware services below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en