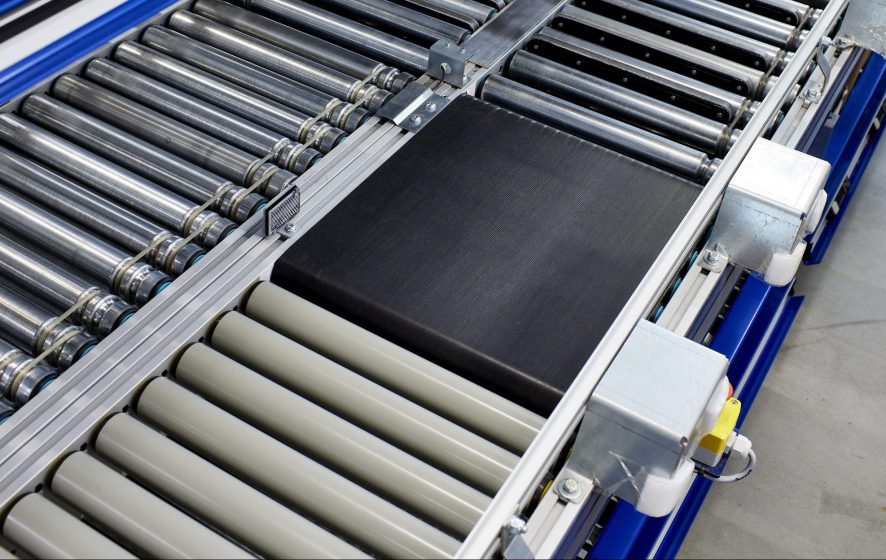

How our goods-to-man system works

The items to be picked are retrieved from an automatic storage system (such as an autostore or warehouse crane) and are getting transported to the operator via a transport system. As a result, the operator no longer has to enter the warehouse himself, but gets the right products delivered to his workstation.

Use of our goods-to-man system

The goods-to-man system is used in the logistics industry. Where items have to be taken out of a warehouse, goods-to-man can ensure a faster and more efficient process.

Advantages of our goods-to-man system

The advantages of a goods-to-man system from ARCO are:

- You have lower operational costs due to the automation of various process steps;

- The goods-to-man system is often combined with an automatic storage system;

- Walking distances are minimized;

- Increased pick activity with a smaller margin of error.

Other possibilities

Interested in our goods-to-man system, but also looking at other options? We also offer complete sorting lines such as the pick-to-light system or the put-to-light system. These sorting lines can be used for quick picking and placing of warehouse items. Contact us for advice tailored to your organization. ARCO likes to think along with you.

Add-ons to our hardware solutions

As a system integrator, we always want to stay one step ahead of the competition. We realize this with products that not only provide better performance, but are also stable, safe and sustainable. This requires optimal maintenance of our installations, easy options for making upgrades and the flexibility to respond quickly and efficiently to changing market requirements. To achieve this, you will need more than good service only. View the supplement to our hardware services below.

What our customers have to say

Want to know more?

Feel free to get in touch – we are more than happy to discuss all the possibilities, together.

Malfunction? Please, contact us

Our technical experts are always looking for a new challenge. Has your company encountered problems for which there is currently no solution? Here at ARCO, we are known for delivering innovative, customized solutions.

- Our knowledge is your knowledge

- We never stand still

- Going beyond the best solution

en

en